Details

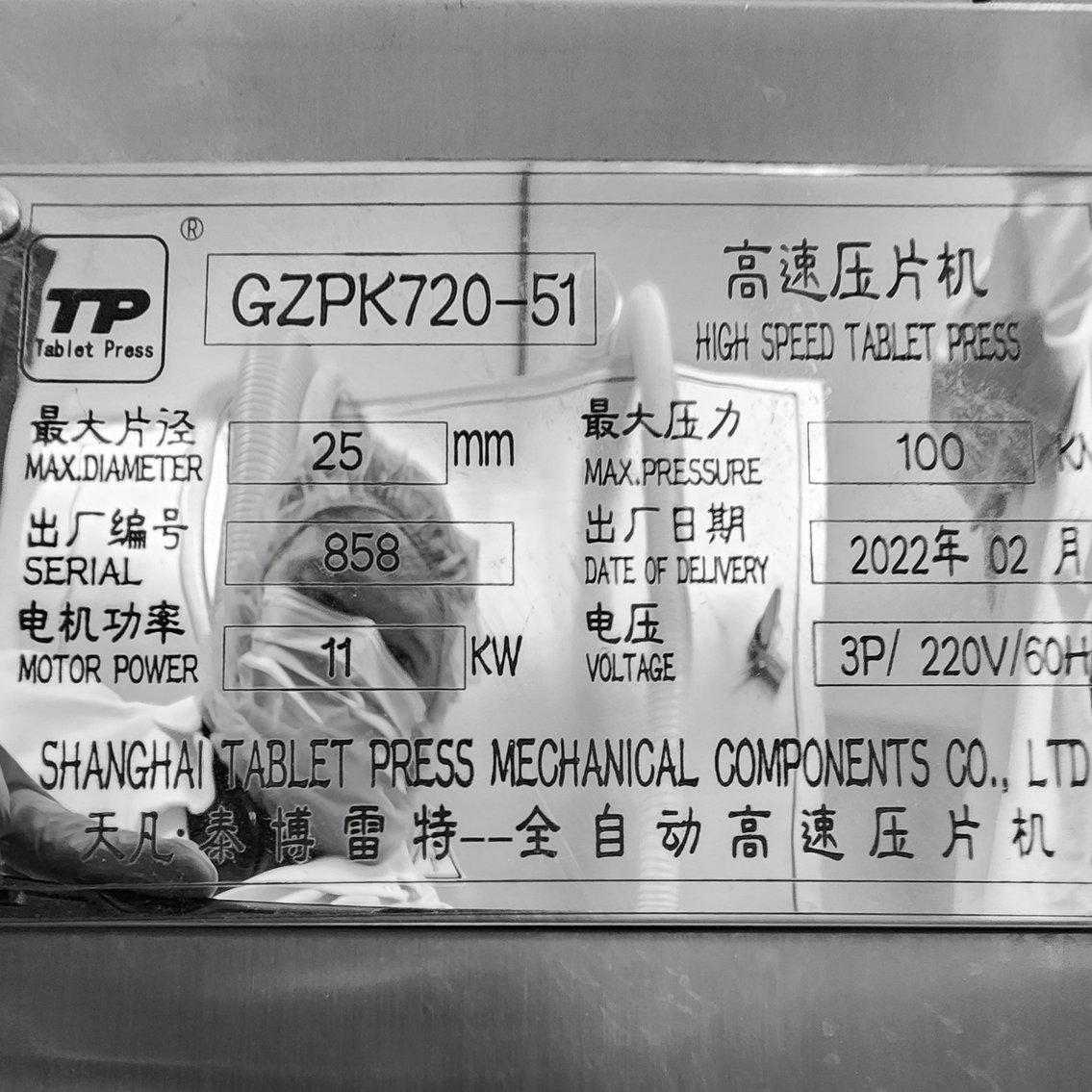

1- GZPK720-51 Station Tablet Press

Model: GZPK720-51

Serial: 858

Max Capacity (pcs/h) 47000-470000

Motor powder (kw) 11

Max pre-press (kn) 100

Max main-press (kn) 100

Max tablet diameter (mm) 25

Max filling depth (mm) 20

Max tablet thickness (mm) 8.5

Pitch cycle diameter (mm) 720

Punch shank diameter (mm) 16

Middle model height (mm) 23.8

Punch length (mm) 133.6

Overall Size (mm) 1585*2079*2000

Weight (kg) 5500

Extra Equipment it comes with:

Upward De Duster

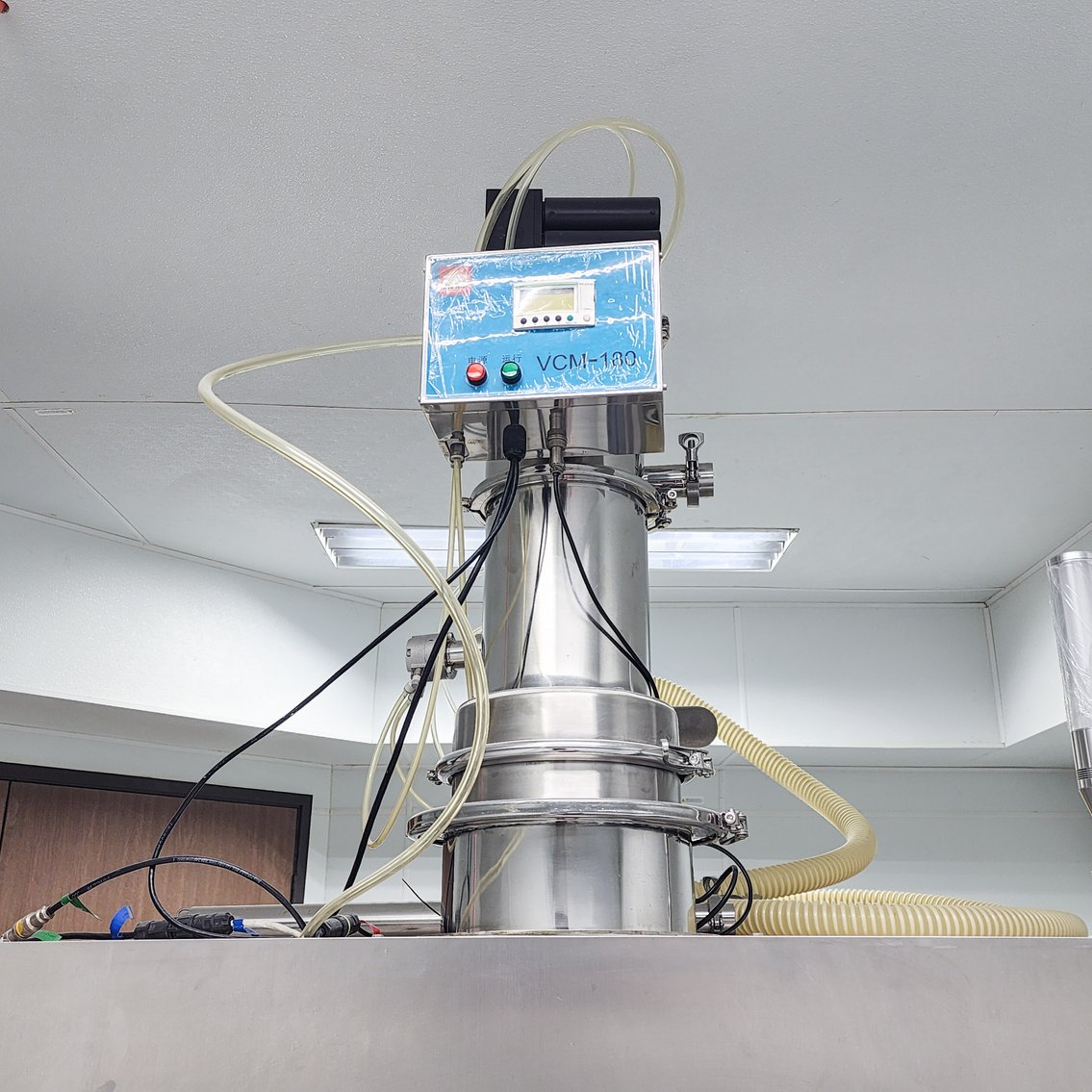

Industrial Vacuum

Vacuum Powder Loader

The GZPK Series High-Speed Tablet Press is an advanced, fully automatic machine designed for efficient tablet production. It operates through a two-stage pressing process: first, granules are pre-pressed using a pair of pre-press wheels, and then they are compressed into tablets by a pair of main press wheels.

To ensure optimal tablet quality, granule materials must meet specific criteria:

For tablets weighing less than 0.3 grams, granules should be sieved through a 16–20 mesh screen.

For tablets weighing more than 0.3 grams, granules should be sieved through a 10–14 mesh screen.

The granule moisture content should be between 1% and 5%.

Half-solid powders, damp powders, and fine granules are not suitable for this tablet press.

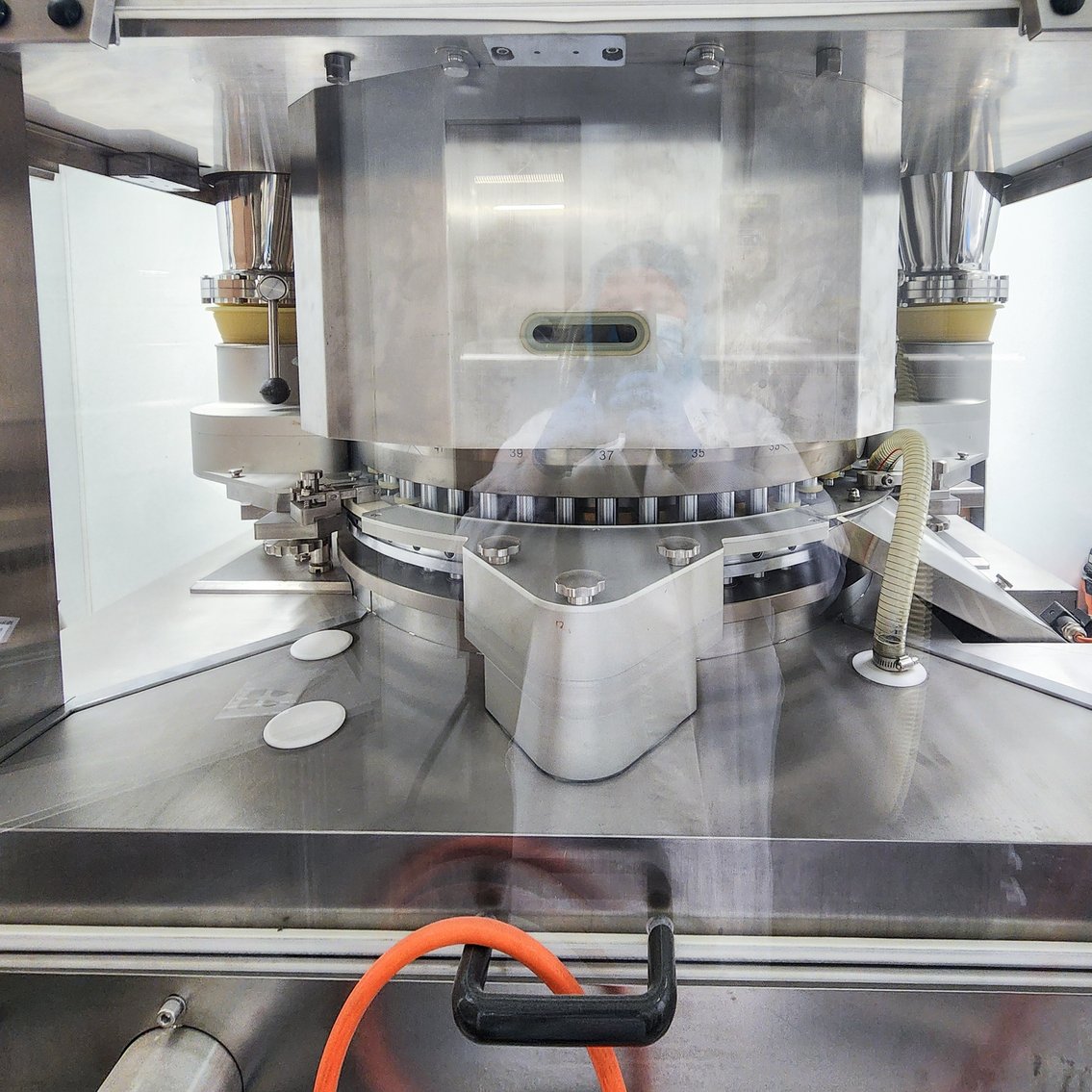

The -51/65/83 Series models feature a fully sealed tablet press chamber, constructed entirely from austenitic stainless steel for all parts in contact with the powder. Non-metal components are made from harmless materials. The machine includes four transparent, easily removable windows for simple cleaning.

The lower part of the machine is enclosed by a stainless steel door, housing the drive components to ensure safety and reduce noise. The tablet press process involves five key steps: filling, measuring, pre-pressing, main pressing, and tablet discharging. Operation is controlled via a user-friendly touch screen located on the electric cabinet.

The GZPK720 model boasts a robust four-column supporting structure. With an overall height of just 1981 mm and a low center of gravity, the equipment offers exceptional stability during operation.

Location: Anaheim, CA