Details

1- GUMMY COUNTER AND FILLING SYSTEM - WEIGHPACK PRIMOCOMBI, SPINDEXER ROTARY INDEX FILLING

*PURCHSED NEW IN 2020, NEVER USED IN PRODUCTION

INCLUDES:

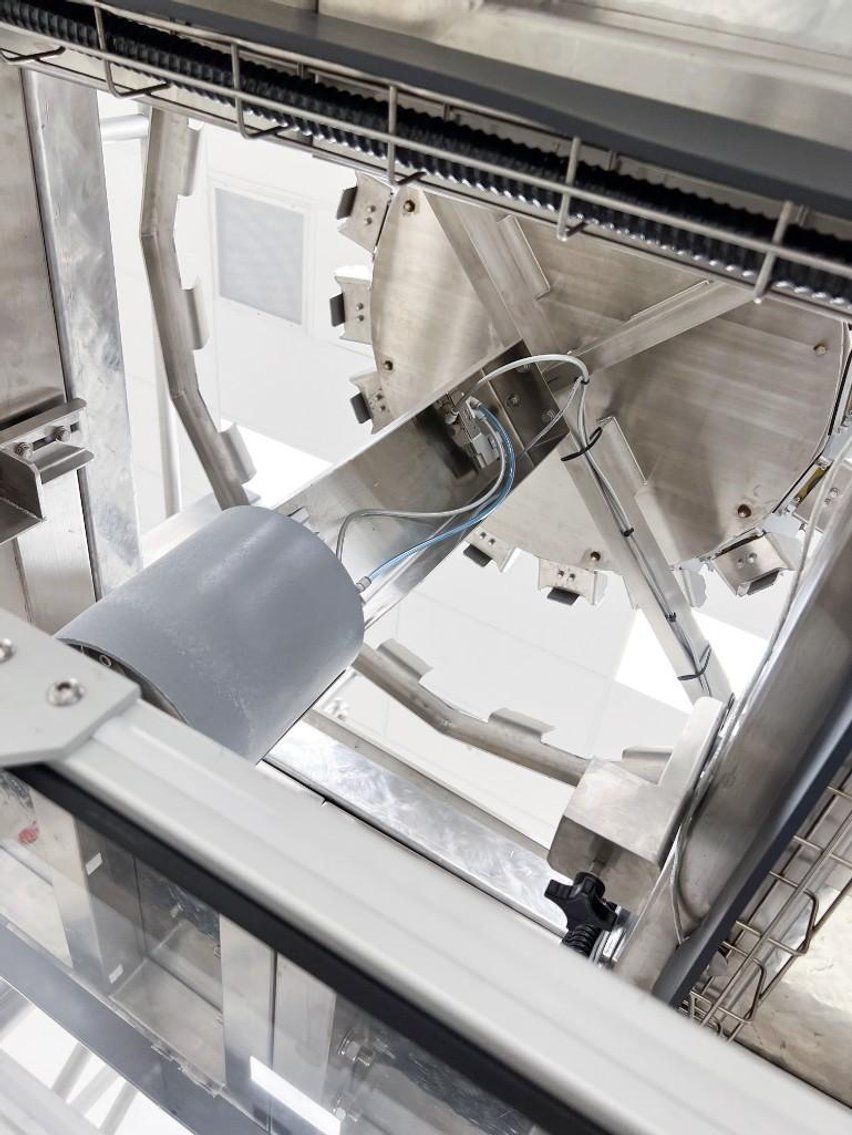

WEIGHPACK PRIMOCOMBI 16 HEAD 2.5L MULTI- HEAD SCALE

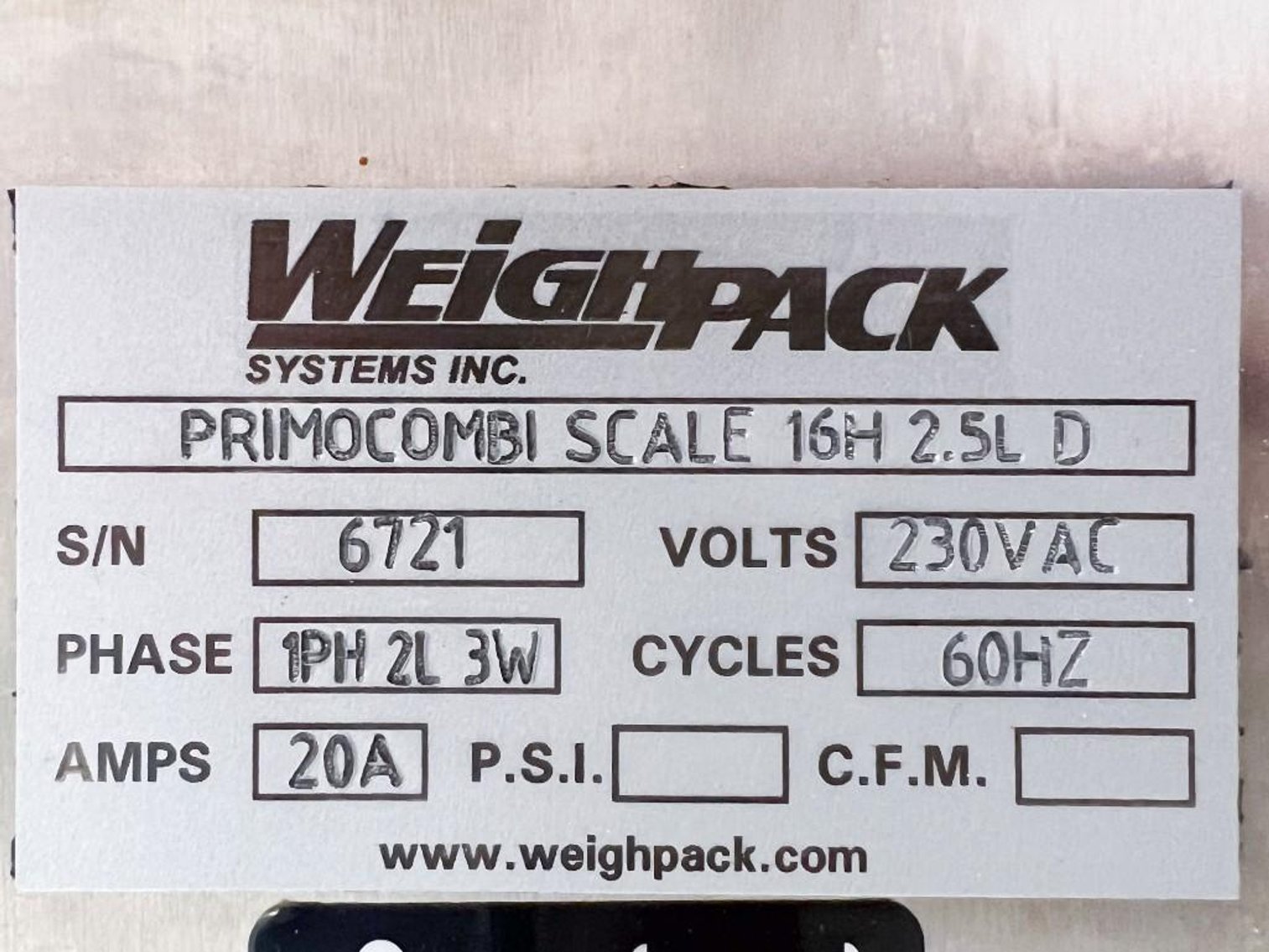

1- Weigh Pack Primocombi 16 Head 2.5L Multi- Head Scale

MDL: PRIMOCOMBI SCALE 16H 2.5L D

S/N: 6721

Volts: 230

Phase: 1PH 2L 3W Amps: 60 Hertz

PC Operating System

Overhead IP-65 Digital Camera

The process starts by filling the center of the PrimoCombi scale with bulk product; product will then vibrate from the center cone to the individual vibratory feeder pans. These feeder pans will then transport product to the weigh bucket where it will be weighed and measured. Once weighed, the PrimoCombi’s PC will determine which buckets equal a near perfect match, once that match is chosen it is then locked and the buckets will dispense at the same time to the automatic packaging machine or a person manually packaging. The term multi-head weighing or combination weighing is derived from the fact that you are using multiple buckets or a combination of weigh buckets to achieve a weight.

PrimoCombi 0.5L multi-head weigher can weigh and dispense as little as 1 gram and is accurate to less than a tenth of a gram. PrimoCombi is commonly used in applications where giveaway cannot exceed one full piece of product or typically several grams.

PrimoCombi multi-head weigher should always be considered for projects requiring more than 30 packages per minute and can be used in applications requiring up to 200.

POWER DISTRIBUTION PANEL

1- Power Distribution Panel

Serial Number: A111414-805

Volts: 230 V AC

Phase: 3PH, 3L, 4W

Hertz: 60

Amps: 40A

CFM: 9

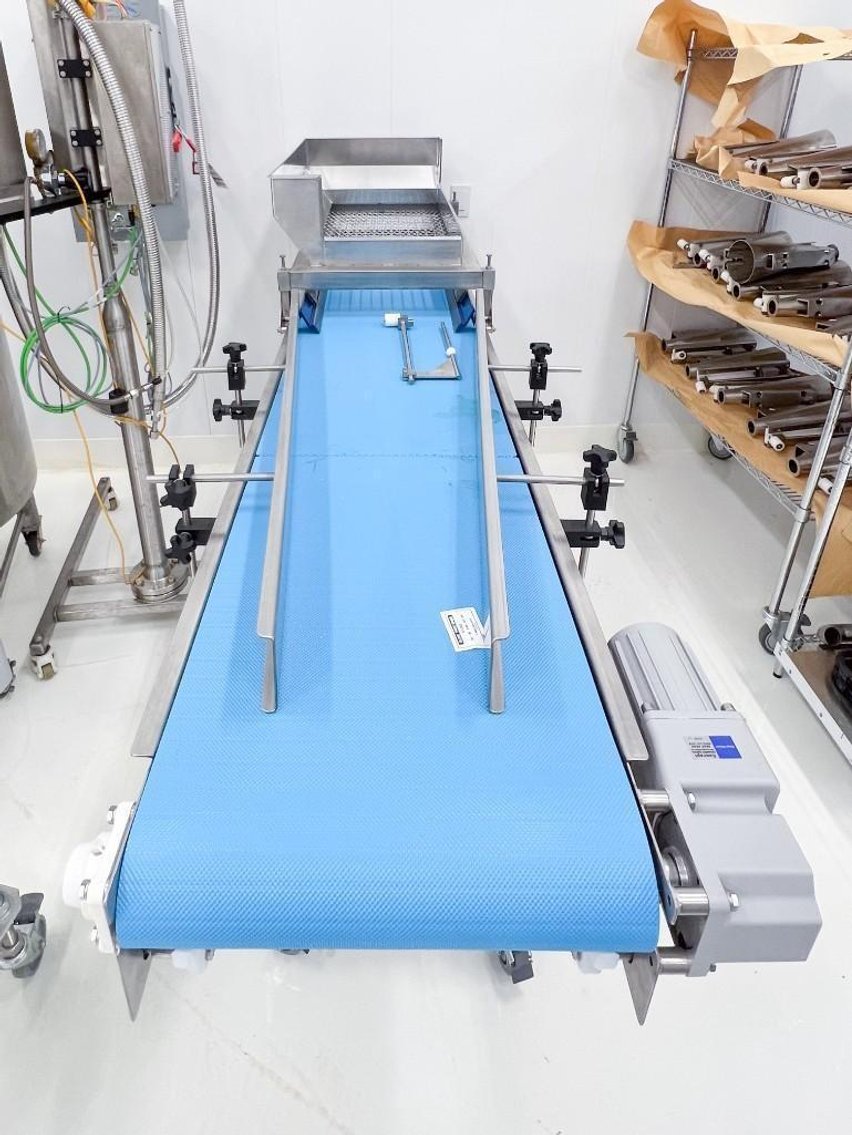

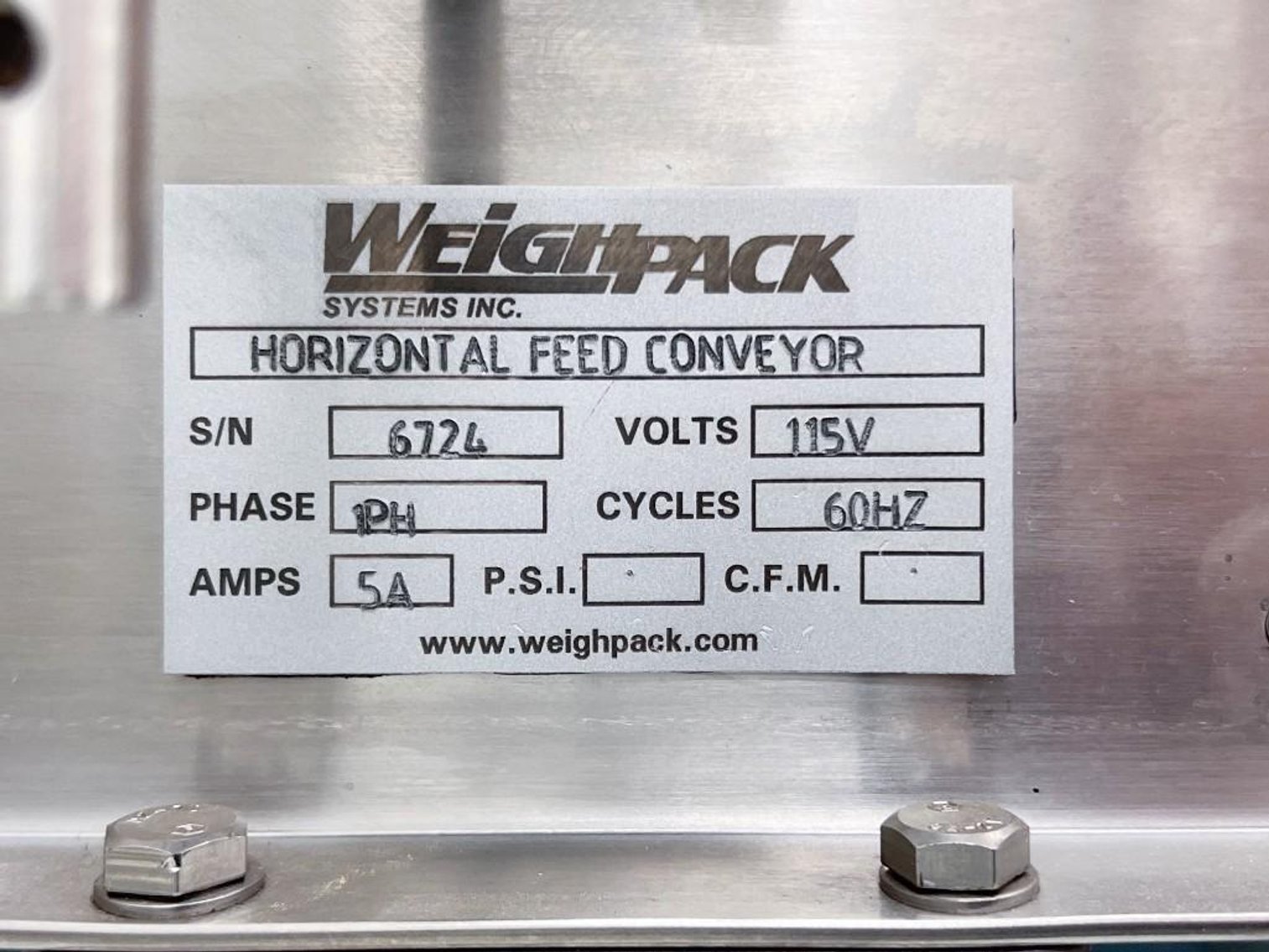

HORIZONTAL FEED CONVEYOR

1- Horizontal Feed Conveyor

Serial Number: 6724

Volts: 115V

Phase: 1PH

Hertz: 60

Amps: 5A

Incline Feed Conveyor with cleated belt on Casters

1- Incline Feed Conveyor with cleated belt on Casters

Catch pan underneath for fallen product

Stainless Steel Mezzanine 100” x 100”

1- Stainless Steel Mezzanine 100” x 100”

Includes Staircase

Diamond Plated floor

Support legs

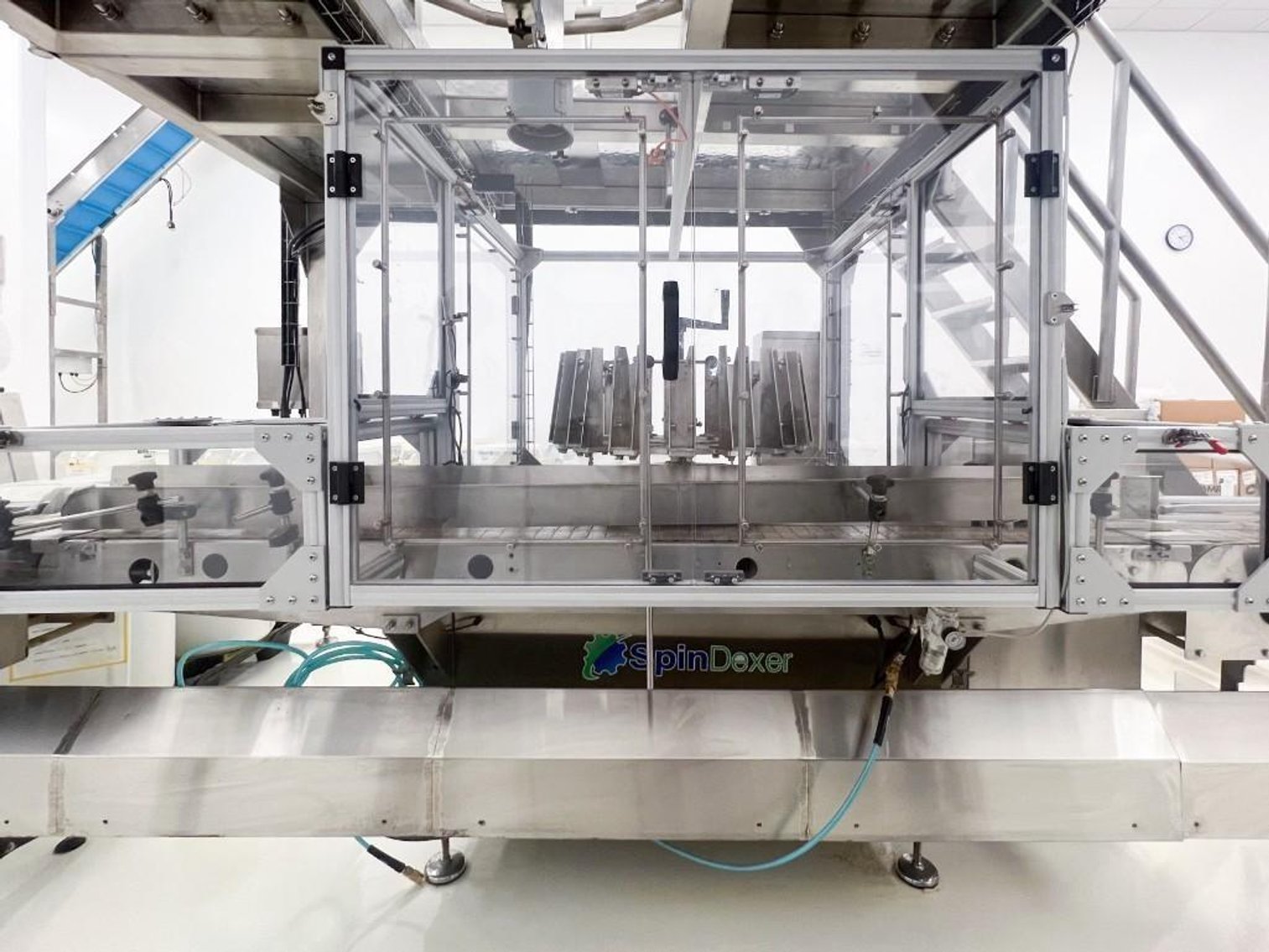

SPINDEXER ROTARY INDEX FILLING MACHINE

1- Spindexer Rotary Index Filling Machine

Traveling Funnels

Touch Screen PLC

The SpinDexer rotary indexing conveyor and container filler is engineered for high-speed applications and is perfect for filling narrow containers.

Commonly used to fill jars, cans, tubes and containers with products ranging from confections, snack foods, frozen foods and produce to hardware, pharmaceuticals, cannabis and medicinals.

Features

Variable speed infeed / discharge conveyor

Single station fill spout

Servo drive

No container—no fill sensor

Totally enclosed, Lexan safety covers• Safety switches & E-stop

304 Stainless steel contact parts

304 Stainless steel frame

Food grade materials

Full adjustable side rails

Readily interfaces with weighing equipment

Anti-vibration leveling pads

Omron PLC

Color HMI

SPINDEXER CONVEYOR L-R

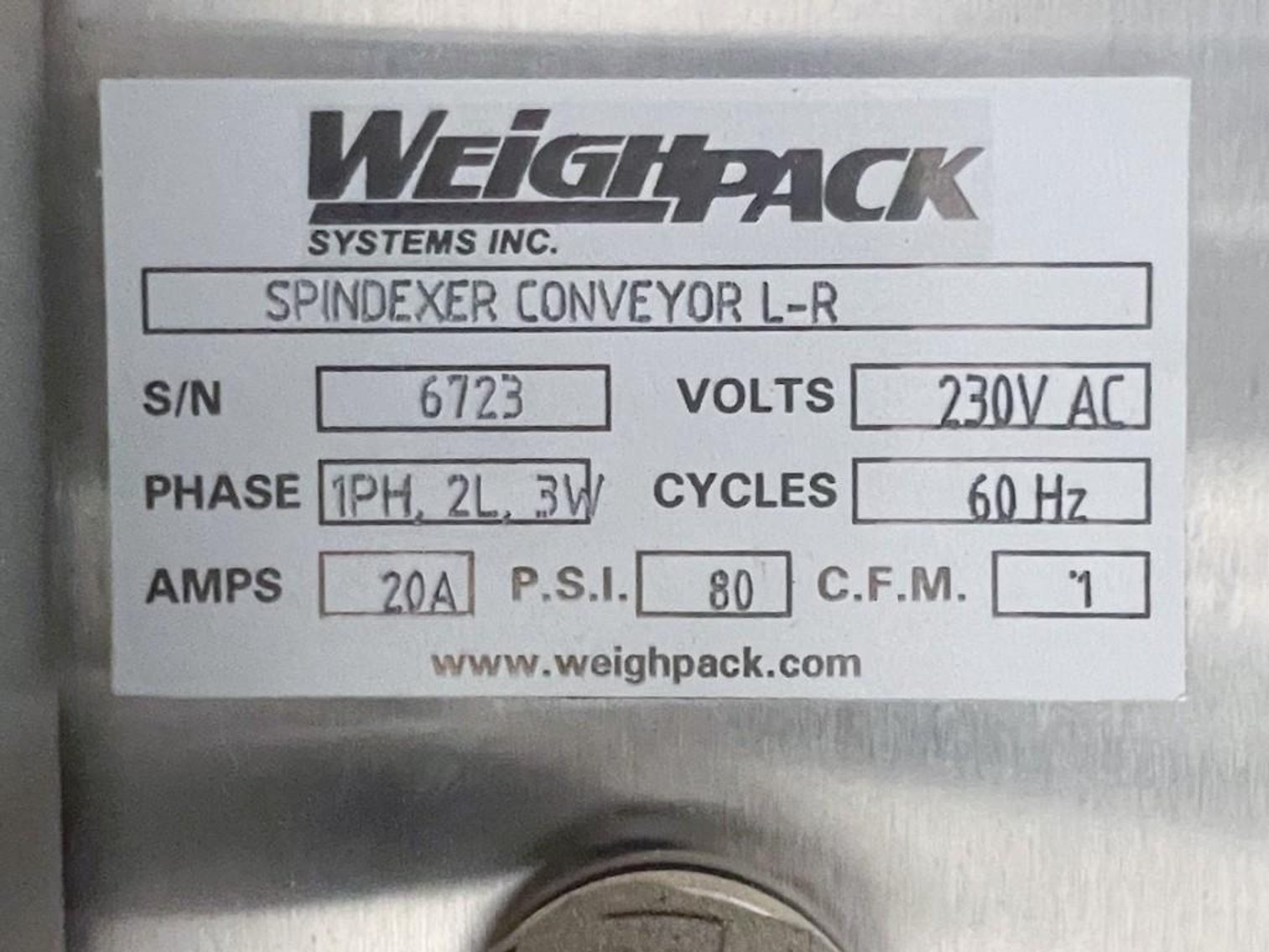

1- Spindexer Conveyor L-R

Serial Number: 6723

Volts: 230

Phase: 1, 2L, 3W

Hertz: 60

Amps: 20

PSI: 60

2 SETS OF TOOLING- 750CC, 250CC

Horizontal Feed Conveyor

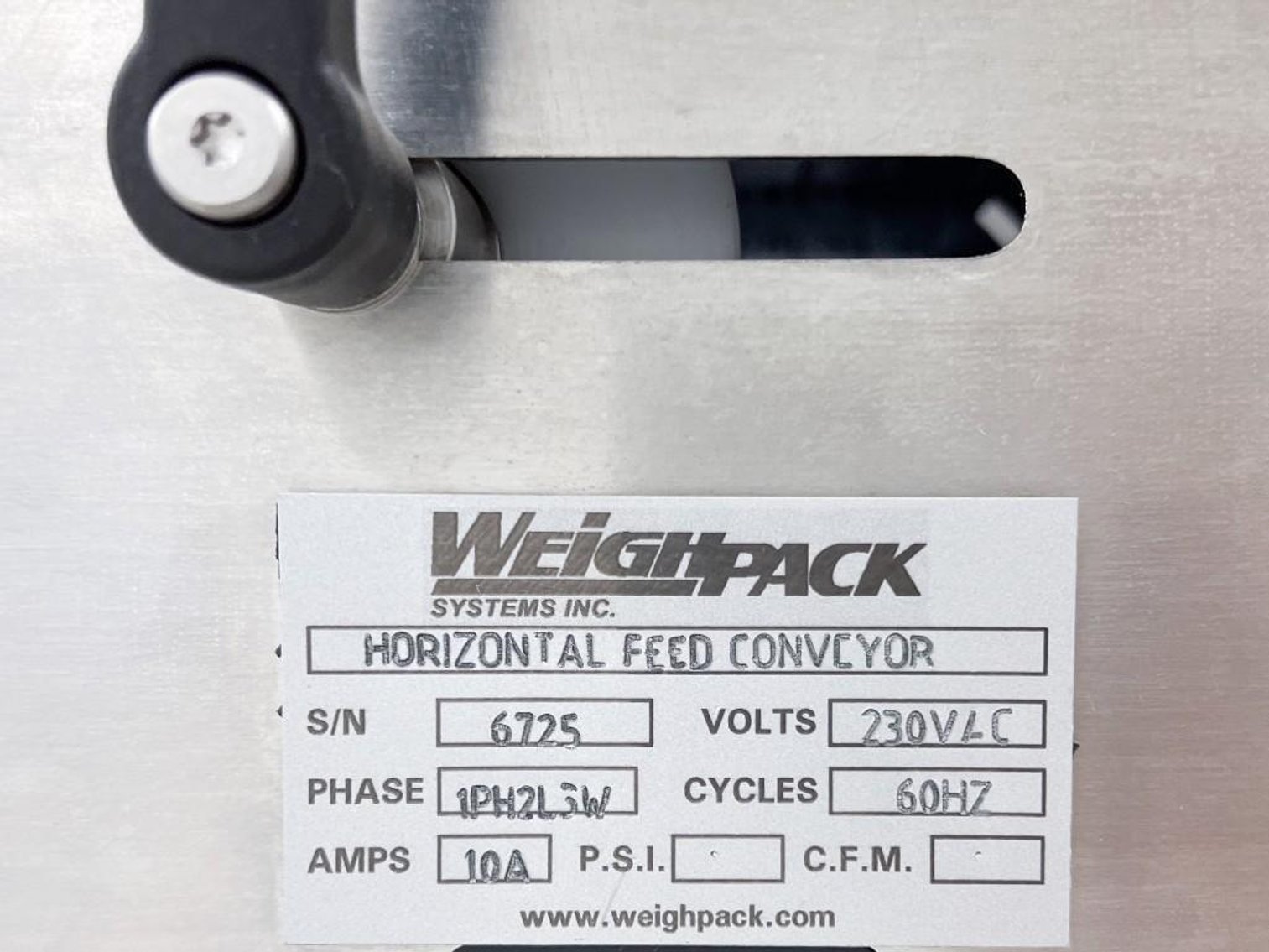

1-Horizontal Feed Conveyor

On top of scale

Serial Number: 6725

Volts: 230

Hertz: 60

Phase: 1

Amps: 10

1- Stainless Steel Mezzanine 100" x 100"

Includes Staircase

Diamond Plated floor

Support legs

Skidding: $ 4,550

Loadout: $11,400

Location: Chandler, AZ