Details

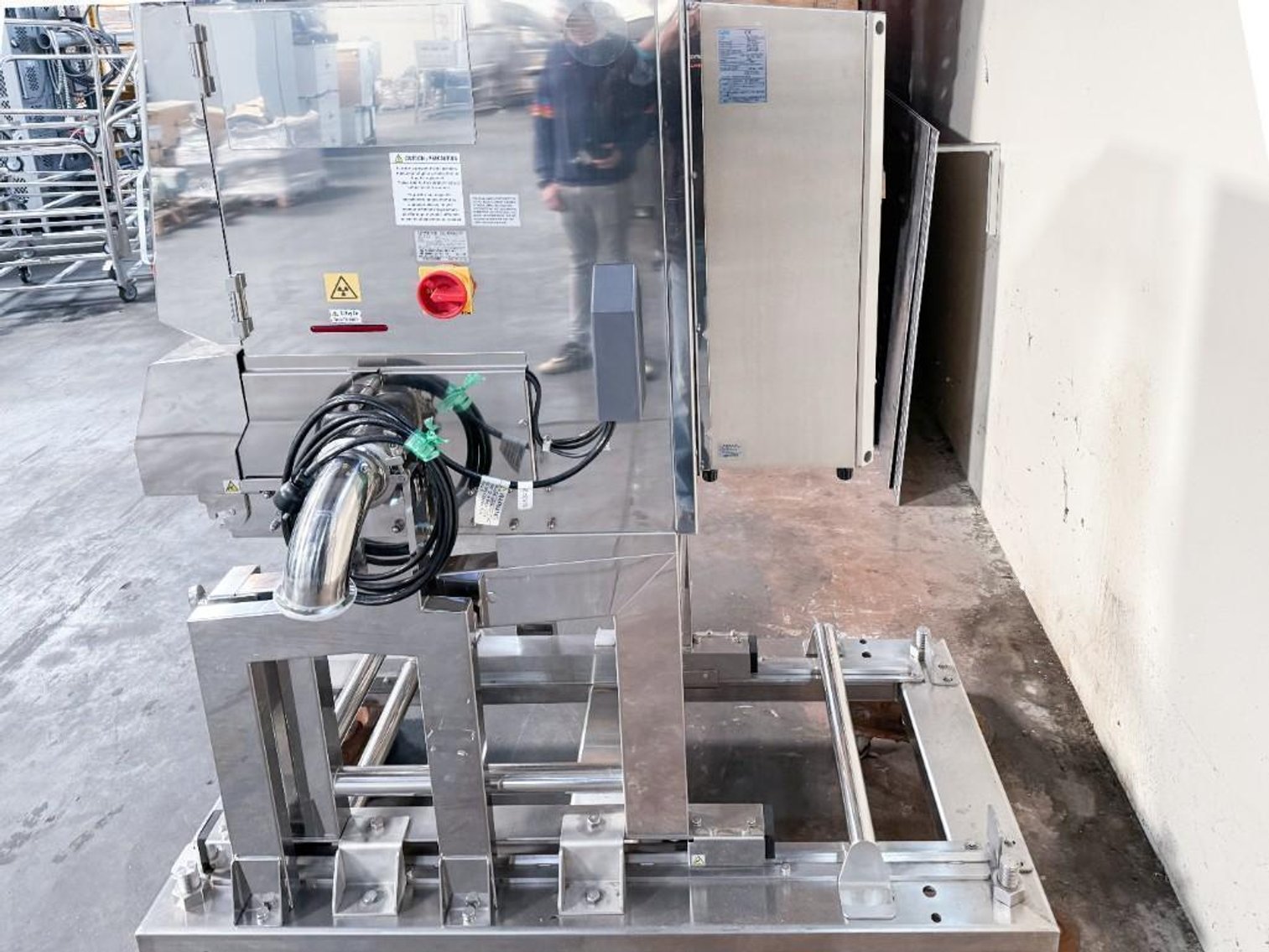

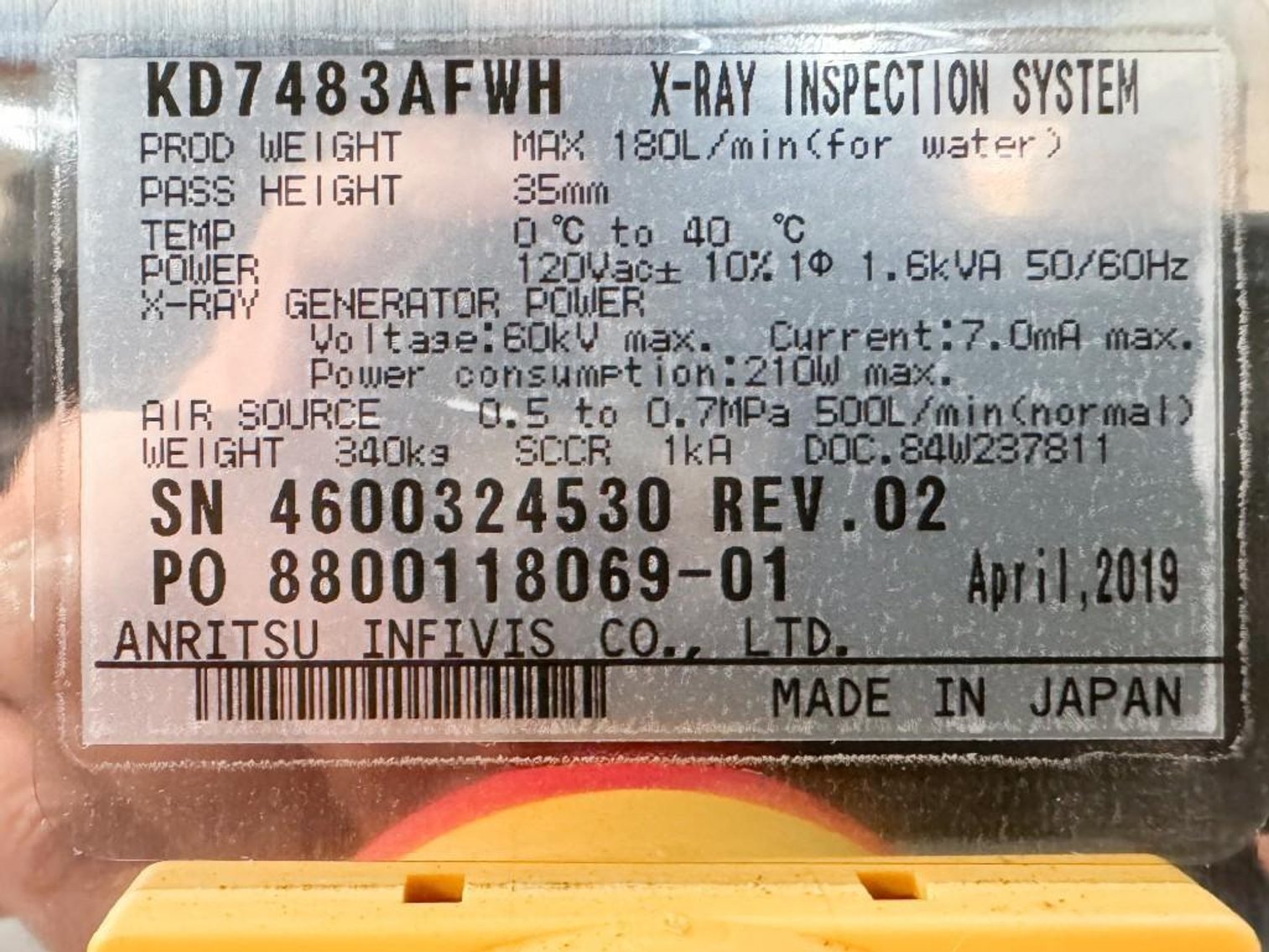

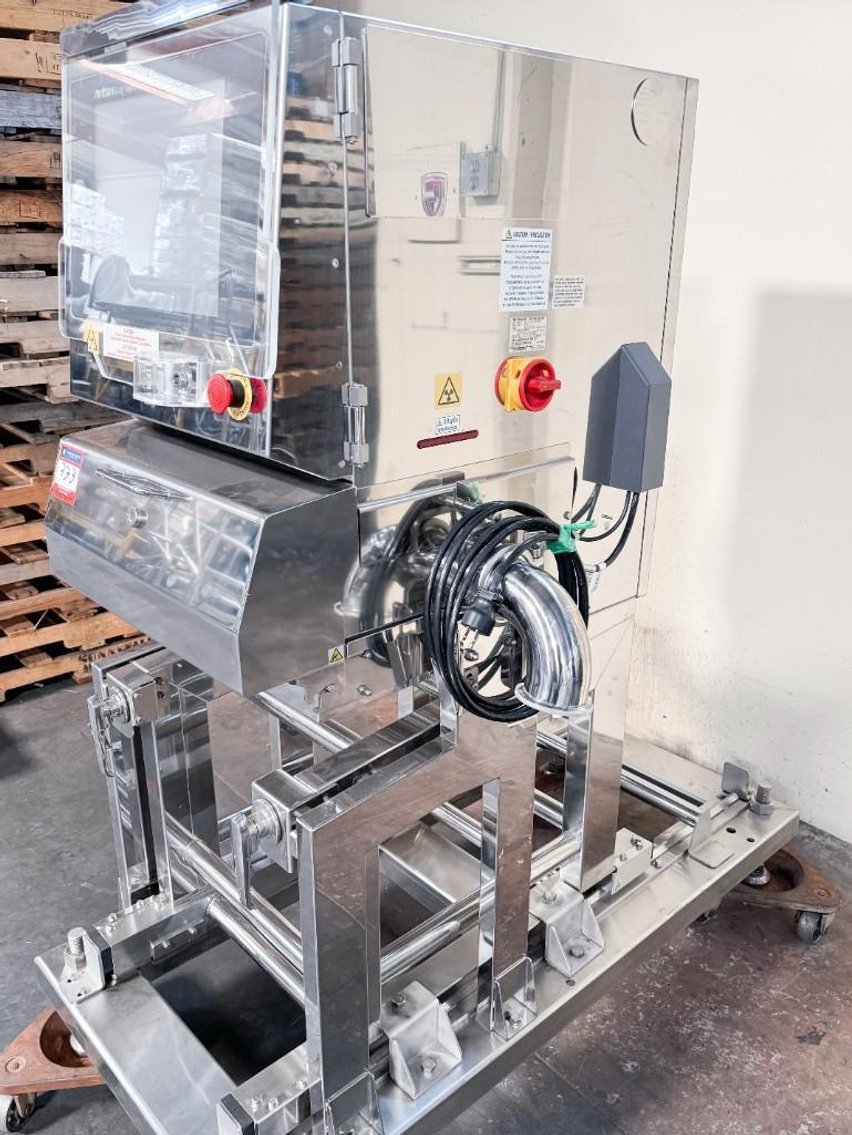

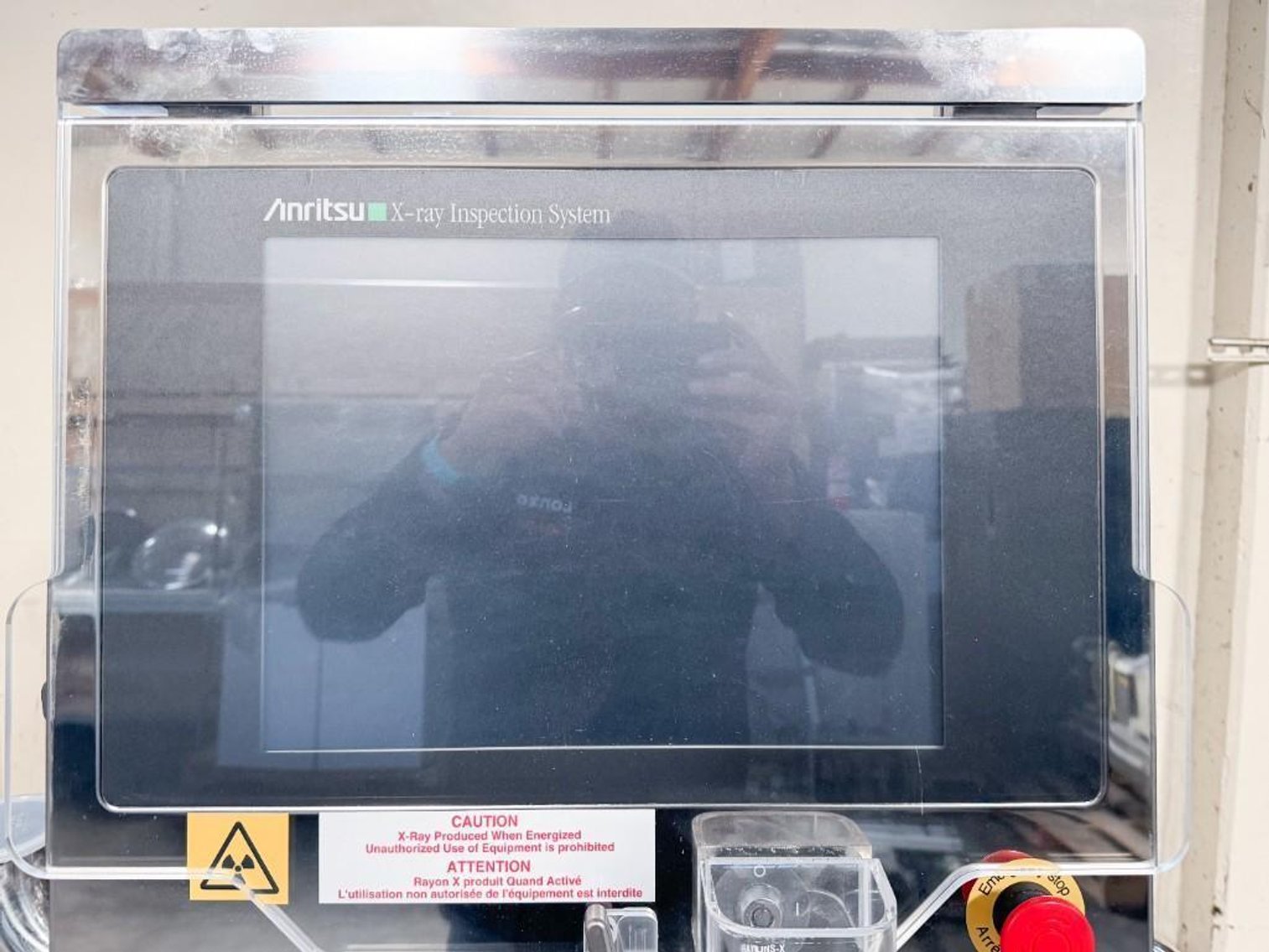

1 - Pipeline Inspection X-Ray Inspection System

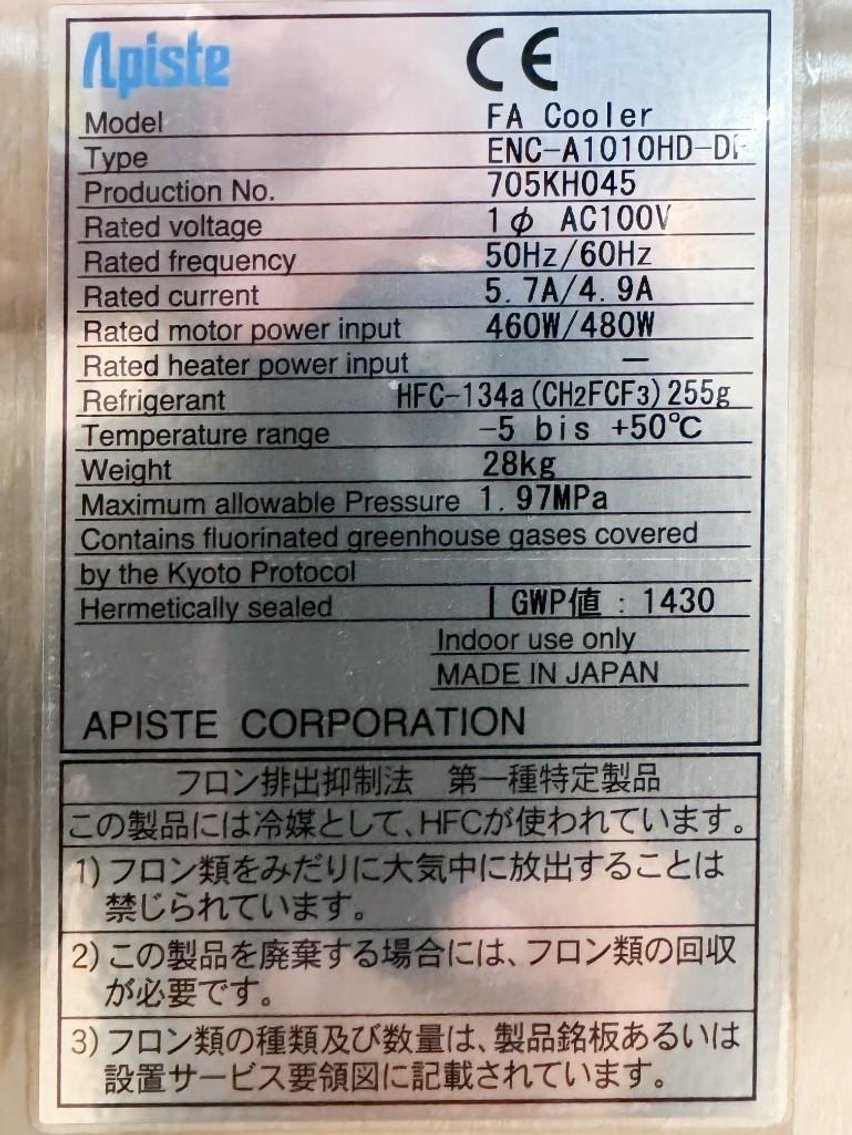

MDL FA Cooler

Type ENC – 81010HD – DF

PROD NUM: 705KH045

S/N: 460-032-4530

MFG: 2019

MAX 180L/min (for water)

TEMP 0’C -40’C X-Ray

Generator Power 60KV

MAX 180L/min (for water)

TEMP 0’C -40’C

X-Ray generator power

60KV max.

Power consumption

210W max.

Pass height 35mm

Rated voltage, 460 W/480 W

Made in Japan

World Class Reliability

Anritsu x-ray inspection systems have evolved over the years, and have been installed globally in the food and pharmaceutical industries. This history of reliability is built into every design, backed by our preventative maintenance crew.

Long-Term Flexibility

The Anritsu x-ray system includes virtually every algorithm you may need to inspect your product. In addition, features such as variable speed conveyors, variable power x-ray source, color LCD touch panel, Ethernet connection and many other features provide the user with a long-term, flexible solution for any new applications that may require x-ray inspection.

Ease of Use Increases Efficiencies

Anritsu installations are successful because they are designed to be easy-to-use and easy-to-understand. Rather than requiring complete knowledge of the technology, graphs and color-coded algorithm feedback provides operators with the information required to create new products and adjust existing settings with ease, eliminating the need for factory support.

Ease of Maintenance

Reliability in the design minimizes the need for maintenance, but when required, a full suite of system diagnostics, plug and play boards and easy release conveyor design offers quick maintenance and minimizes any downtime.